XPDYT (‘expedite’)

is the performance machining and integrated composites division of

aerospace leader Nashero S.R.L

We use oversize 5-axis CNCs, purpose built fixtures, proprietary composites forming methods, advanced process automation and integrated metrology to bring you aerospace quality parts with repeatable precision and incredibly quick turnarounds at exceptional value.

(CERTIFICATIONS & RECOGNITION)

MiliTARY

We’re listed with a unique NCAGE NATO code, as a proven mil-grade manufacturer having delivered parts and subassemblies to EU and US primes. Our capabilities cover sea, air, land and space vehicles as well as the individual combatant.

AEROSPACE

We have a special purpose practice to support aerospace prototyping, R&D and experimental development including advanced components for Civil Aviation (fixed and rotary), Urban Air Mobility (UAM) and heavy-lift Drone components.

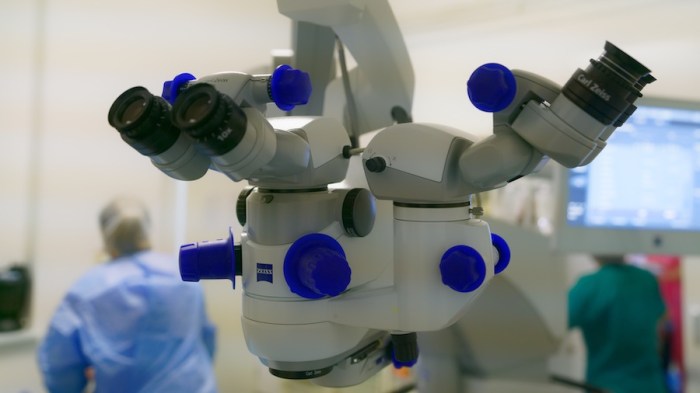

MEDICAL

Whether it is saving a life or discovering a life-saving drug critical research learn more about how XPDYT brings cutting edge military and aerospace knowhow to medical instrument manufacturing includes full traceability.

WE’RE GOOD AT THIS

REPEATABLE PRECISION

Our industry leading benchmarks for ‘repeat precision’ not only has its roots in our aerospace background but in core philosophy of how we build things right – reflected in every step of our production workflow, not just at the end.

FAST TURN AROUND

The process foundations we laid for our ‘repeat precision’ philosophy also the enable us to turn around complex parts to exacting specifications, sometimes up to 30% less time and effort than most companies our size.

PRODUCTION ON-DEMAND

Whether we manage your order on a turnkey basis or you as ‘burst capacity’ for your production line – all our capabilities – end to end automation and on-site inventory is all on-tap at a moment’s notice.

What they are saying!

Our production order with the XPDYT team was an unbelievably smooth experience. Precision engineering was in play all through – from spec review and acceptance to the thoughtful communication, craftsmanship and quality hand-off of finished parts. Truly exceptional!

– XPDYT Customer

At XPDYT we don’t just ask our customer’s to use our products. Heck – we use them too! Click here to learn more about how CEO, Dr. Naresh Sharma is building his own single engine plane to fly solo across the world. Now that’s walking the talk!

THE XPDYT DIFFERENCE!

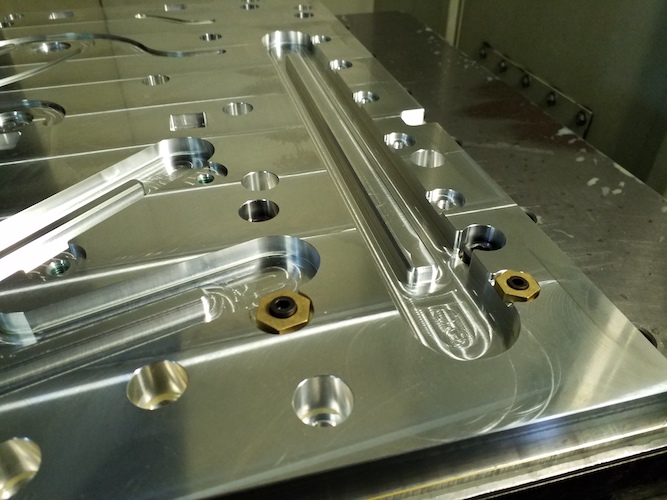

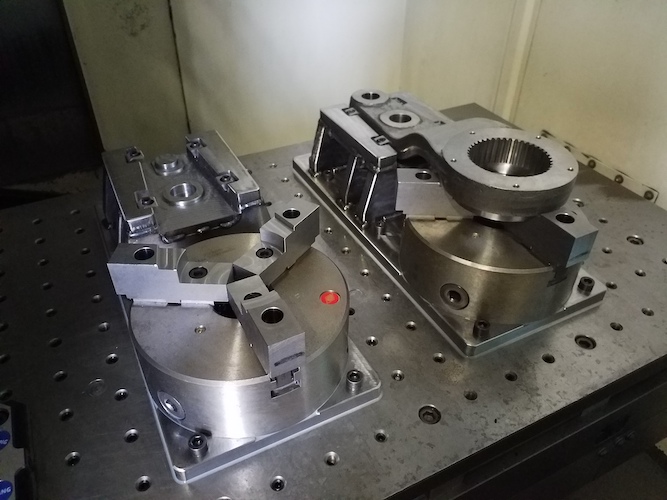

SUPER-SIZED MACHINES

Our machines have larger bed sizes than those typically in use by others and are capable of producing multiple part sets in fewer steps, thereby reducing errors, variances and turn around time.

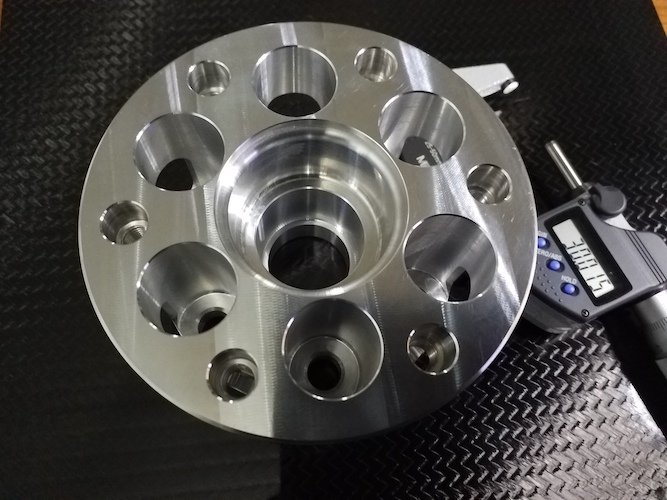

INTEGRATED METROLOGY

Precision for us is not an afterthought. Our metrology equipment is deeply embedded in the machining process itself thereby reducing errors, variances and turn around time.

REAL-TIME VISIBILITY

Our Industry 4.0 setup means that we can provide your team a dedicated secure access to our real-time production data so you can monitor status, quality and production real-time!

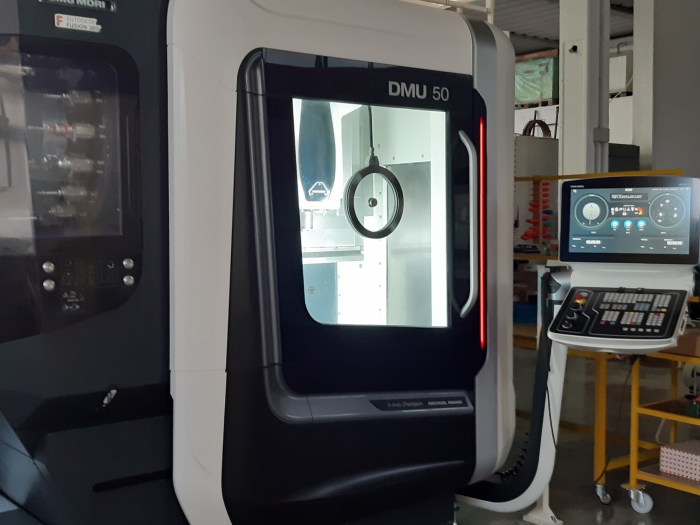

EQUIPMENT

We use the state of the art Swiss tool holders and Swiss, German and Swedish tools. Equipment: DMGMORI continuous 5 axis CNC machines.

CAD and CAM programming use best in class Siemens PLM and Autodesk software in both.

LIMITS & TOLERANCES

We can machine metal parts to sizes as large as 1000mm x 600mm x 400mm. This dramatically reduces variance and turn-around time.

We achieve consistent dimensional tolerances within ±7 microns or 0.000275″ and ±2microns on holes.

Materials

We can supply machined and fully finished parts in a wide range of metals and alloys . These include:

Ti6Al4V

Al alloys 7075, 2017, 2024 etc.

Superalloys

Carbon composites